Production and Repair Service

Service Center Mechanical Machining

Service Center Mechanical Machining

Service Center Compressor Systems

PRODIS covers the maintenance and professional, competent Mechanical Machining of engines and components. This service system is based on two conditions: Maximum efficiency for our customers through full service and optimized and efficient project and quality management.

Our services refer to the following engine manufactures:

- AGCO Sisu Power

- Allweiler Pumpen

- Caterpillar

- Craftsman

- Cummins

- Deutz / MWM

- Farymann FPT (Fiat Power Train)

- GE Jenbacher

- Hatz

- JCB Power

- Kubota

- Lister Petter

- Lombardini

- MaK

- Mitsubishi

- Perkins

- Scania

- SCHNELL

- Steyr

- Waukesha

- Yanmar

- Sonstige

Services for the overhaul and production of machines and engine components

Performance and services

- Extensive capacities for the mechanical machining of components

- Reconditioning of engine blocks and bed plates

- Reconditioning of cylinder liner seats with L and Z rings

- Reconditioning of cylinder heads, valves, valve seats, cylinder sleeves and pistons

- Laser measurement of main bearing grooves

- Drilling of main bearing grooves

STORM Special Services

- Own production of slide bearings

- Crack testing of components and material

- Service for injection pumps and industrial pumps

- Reconditioning of spindle pumps

- Overhaul of components from industrial plants and compressors in our factory as well as on-site

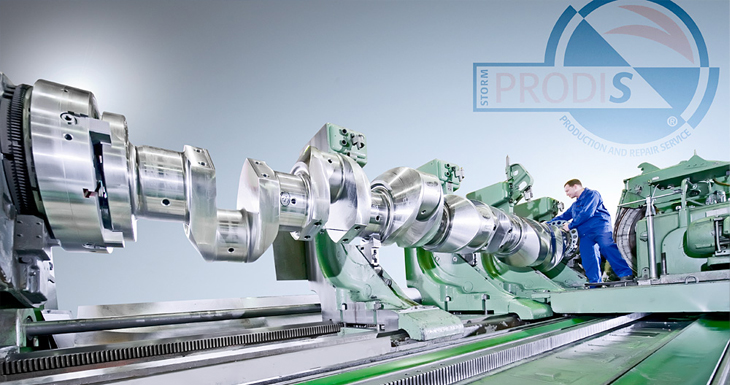

Crankshaft grinding

- stroke up to 350/700 mm

- length up to 8,000 mm

- oscillation circuit up to 1,750 mm

- capacity up to 12 t

Surface grinding

- length up to 1,000 mm

- width up to 400 mm

Internal grinding

- diameter up to 250 mm

- length up to 250 mm

Cylindrical grinding

- length up to 2,200 mm

- diameter up to 480 mm

Honing

- stroke up to 3,000 mm

- diameter up to 700 mm min. diameter of 8 mm

CNC boring mills and milling machines

- x-axle up to 3,500 mm

- y-axle up to 2,000 mm

- z-axle up to 1,250 mm

CNC milling with C-axle

- x-axle up to 700 mm

- y-axle up to 500 mm

- z-axle up to 600 mm

Lathing - man operated

- length up to 8,000 mm

- diameter up to 500 mm

CNC operated

- length up to 2,000 mm

- diameter up to 700 mm

Milling - conventional

- x-axle up to 900 mm

- y-axle up to 370 mm

- z-axle up to 250 mm

Metal spraying

- crankshafts up to a length of stroke of 350/700 mm

- length up to 8,000 mm

- diameter up to 1,000 mm

Crack testing

- magneto-flux process

- ultrasound testing of components and material

If you have questions apart from the performance data given above, just give us a call, we will be pleased to help you.

Services covering all aspects of reciprocating piston compressor systems

Full service for reciprocating piston compressor systems

- Maintenance (service, repair and overhaul) in accordance with the PRODIS service plan with qualified service technicians on-site or in our work shop

- Customized, manufacturer-independent maintenance for all conventional reciprocating piston compressor models in the natural gas and petro-chemical industries

Retrofitting and optimizing

Solutions matched to customers requirements for the optimization of the availability and economic efficiency of existing reciprocating piston compressor systems in the following areas:

Technical consulting with respect to the optimization of the operating life und uptime, e.g. in the case of

- Combination of material between cylinder liners and piston rings and rider rings

- Combination of material between piston rods and compression packings

Supply of spare parts

Overhaul of components

- Compression packings, suction and discharge valves

- Crossheads, cylinders and cylinder liners

- Piston rods with a new coating technology

Overhaul of crankcases and cylinders

At our customers’ site and also in our work shop

- Line boring of main bearing pockets and crosshead channels

Additional services

- New production of piston rods, cylinder liners, crossheads and plain bearings

- Valve service

- Reconstruction of base plates

- Measurement using laser technology

- In-house department for measurement and control engineering

Reconditioning and grinding of crankshafts

Max. length: 8,000 mm

Max. weight: 10,000 kg

Max. lift: 350 mm (700 mm)

- Incoming inspection, concentricity check, crack detection and hardness test

- Documentation with a measurement data sheet before and after grinding

- Acceptance test of crankshafts by classification companies

PRODIS Mechanical Fabrication

Head of department

Mr. Danny Aumiller

Fon: +49 5977 73-309

Fax: +49 5977 73-188

Email: aumiller@a-storm.com

Commercial Management

Mr. Christian Thien

Fon: +49 5977 73-164

Fax: +49 5977 73-188

Email: thien@a-storm.com

Distribution

Mr. Jochen Westhues

Fon: +49 5977 73-146

Fax: +49 5977 73-188

Mobile: +49 171 5448328

Email: westhues@a-storm.com

PRODIS Compressor Systems

Head of department

Mr. Danny Aumiller

Fon: +49 5977 73-309

Fax: +49 5977 73-188

Email: aumiller@a-storm.com

Ms. Beate Stiller

Fon: +49 421 67532-75

Fax: +49 421 67532-79

Email: stiller@a-storm.com

Service Coordinator

Mr. Steffen Kerber

Mobile: +49 170 9290532

Fax: +49 421 67532-79

Email: kerber@a-storm.com

Sales Manager

Mr. Marcus Retter

Mobile: +49 175 4345980

Fax: +49 421 67532-79

Email: retter@a-storm.com

Sales North

Mr. Andreas Gerwath-Witte

Fon: +49 421 67532-70

Fax: +49 421 67532-79

Mobile: +49 160 96331466

Email: gerwath-witte@a-storm.com

Sales South

Mr. Manuel Pooth

Mobile: +49 173 5869115

Fax: +49 203 759498-66

Email: pooth@a-storm.com

Mannheim Branch

Mr. Ulrich Wetzel

Fon: +49 621 79905-167

Mobile: +49 175 5787152

Email: wetzel@a-storm.com

Sales Mannheim Branch

Mr. Ralf Stappenbeck

Mobile: +49 160 97923979

Email: stappenbeck@a-storm.com